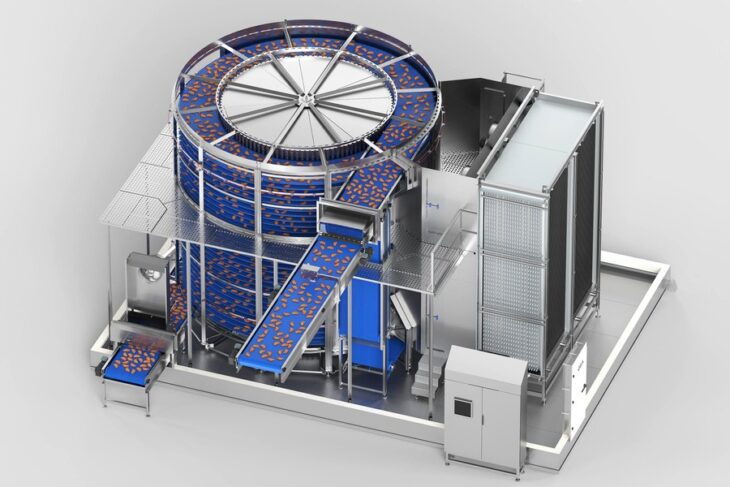

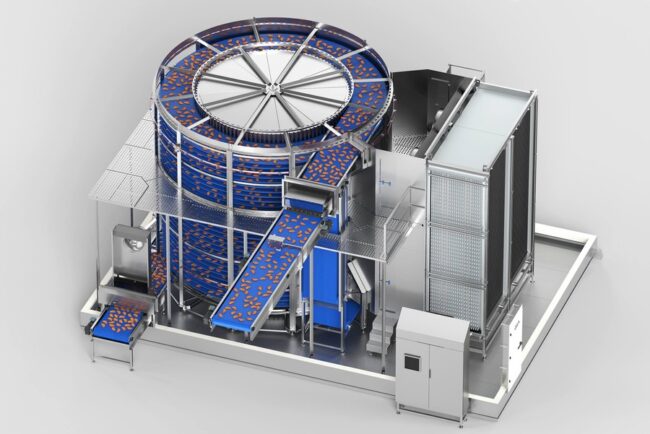

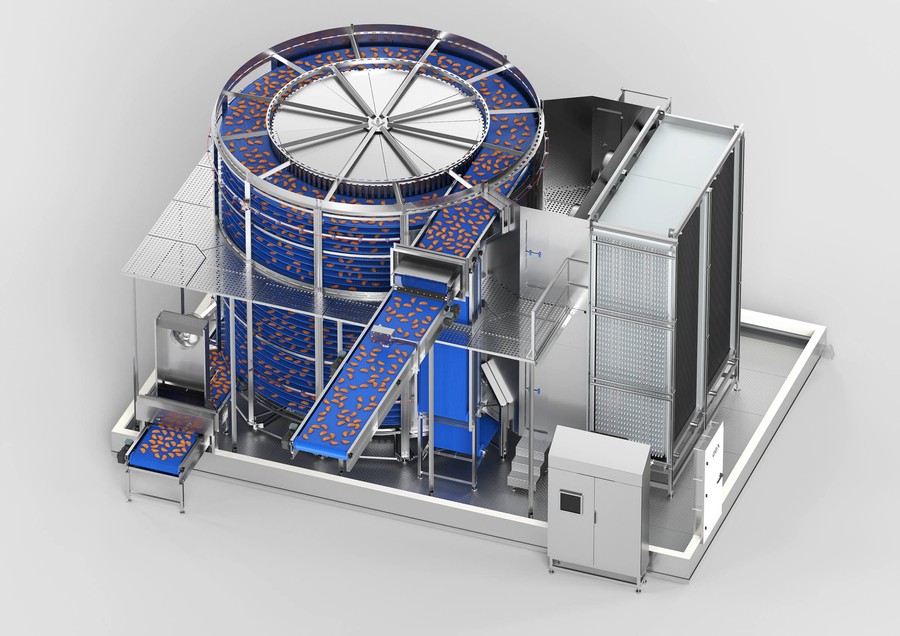

ICS spiral freezers are often considered when processors need high capacity in a compact footprint. Spiral technology uses a vertical conveyor path, allowing product to travel through multiple tiers while staying in a controlled freezing environment. For many factories, that design is attractive because floor space is expensive and production volume keeps growing.

Spiral solutions are widely used for products that move well on a belt and benefit from continuous freezing. Think of poultry portions, burgers, bakery items, pizza toppings, and many ready-to-eat components. The promise is steady throughput, controlled airflow, and efficient use of space.

Why spiral freezing is popular in industrial freezers

Spiral designs can deliver high capacity without requiring long tunnels. This helps when the facility layout is tight or when you want to place freezing near other key steps. A spiral freezer can also offer a smoother product journey, especially when handling uniform items that don’t require individual separation like an IQF freezer would.

ICS spiral freezers are commonly discussed in this category because many buyers want proven spiral performance and a system that can support large-scale operation. As with any equipment, the key is to evaluate the specific model, sanitation design, and support structure.

Product suitability and belt performance

Spiral systems rely on belt transport. That means product must be able to sit stably on the belt without falling through gaps or sticking excessively. If your product is very wet or coated, cleaning and belt release become important factors. If your product is fragile, you need a belt and transfer design that minimizes damage. This is where spiral equipment selection becomes very practical, very quickly.

Hygiene and cleaning realities

Spiral systems can be efficient, but they must also be cleanable. In high-care environments, sanitation is non-negotiable. Look at how access doors are arranged, how drainage works, and how easy it is to inspect critical zones. If cleaning takes longer than expected, the theoretical capacity disappears. In many industrial freezers, hygiene design is a silent driver of profitability because it affects uptime every week.

Balancing capacity, energy use, and control

Spiral freezers can be energy-efficient when airflow and insulation are optimized, but performance depends on real operating conditions. Product load, defrost intervals, and ambient humidity all play roles. Controls should help the system remain stable when input conditions fluctuate. If your line sometimes runs hotter product or varied sizes, you want the freezing curve to stay reliable rather than drifting into inconsistency.

Spiral vs IQF freezer decisions

Processors sometimes compare spiral technology with IQF freezer systems, but they serve different goals. IQF is about individual separation and often a specific quality outcome for loose products. Spiral systems are usually better for belt-friendly items where separation is not the main requirement. The decision becomes clear when you map your product needs and desired end quality.

Choosing the right path with Industrialfreezing.com

Industrialfreezing.com helps companies evaluate industrial freezers based on product behavior, capacity goals, and sanitation requirements. If you’re considering ICS spiral freezers or other spiral options, the right approach is to connect equipment choice to your real daily workflow. When the fit is right, spiral freezing becomes a stable backbone for growth rather than a bottleneck.